Concept rendering I did in Photoshop.

I like beer. Not like, to the level of Supreme Justice Brett Kavanaugh, but enough to be excited about a job that involves beer. No, I didn’t get to drink any, but I got to look at it and think like it.

What does that even mean?

Well, it means think like your client. Not in the sense of not knowing how to arrange type and making things pop to the point it looks like you made it in MS Paint, but rather about the business. What about them? What do they do? Why do people love them? What do they look like? What do they want to look like? Ask questions because with questions come answers and with answers come ideas.

Creativity wasn’t at full blast here as some of the implementations were taken from their other locations—to sort of, y’know, tie it all together. Color palettes, sign styles, etc.

via @Top_Hops on Instagram

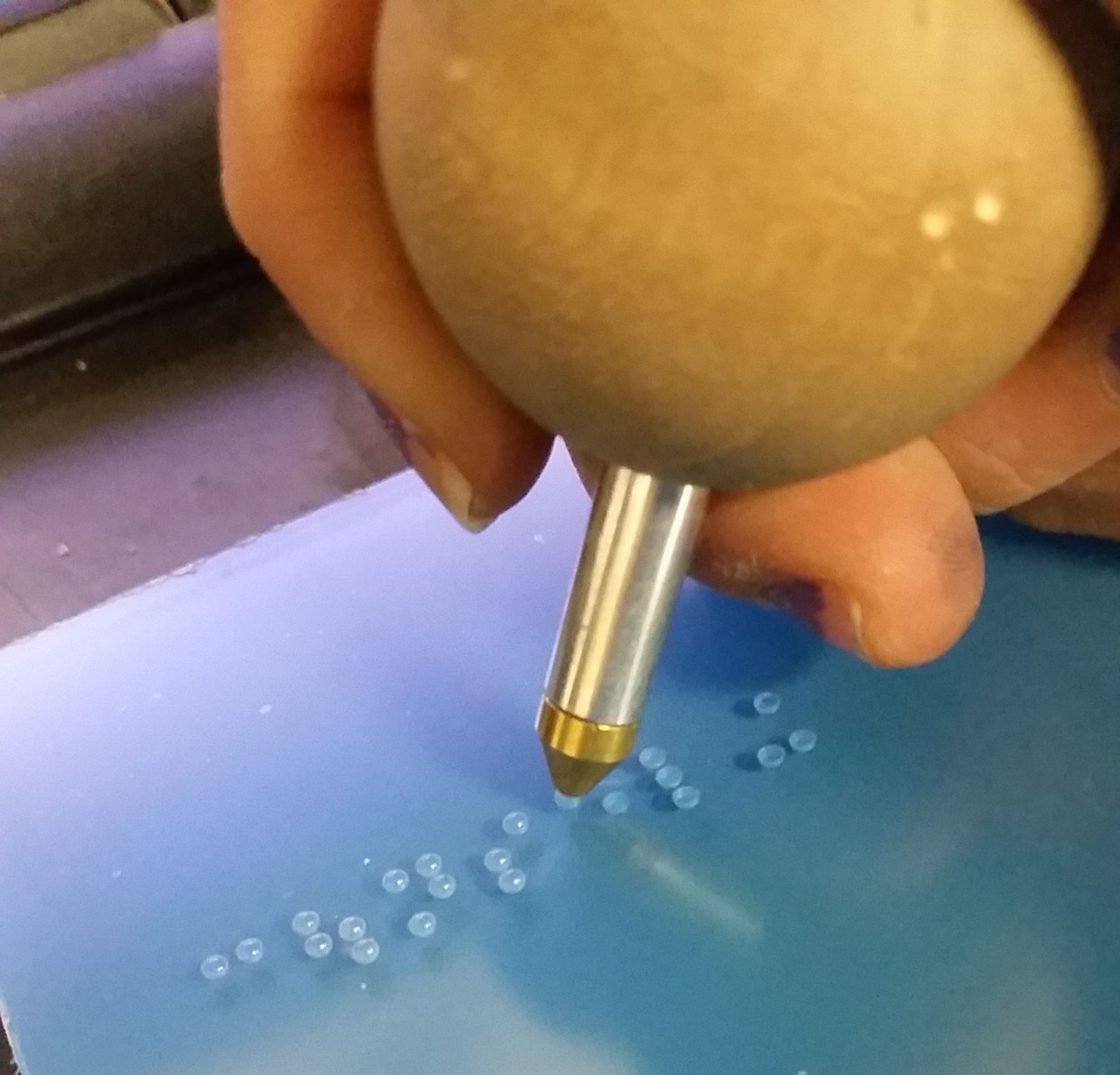

What makes things fun, though, is being able to pull other people into the mix. In this project, we needed (2) hanging bottle signs, (2) chalkboards, one counter stencil and a whole lot of Photoshop work. The bottle signs and counter stencil was easy—send it to the shop. But what do we do with the chalkboards? We could ask the shop to make them, OR…

We can employ a woodworker who makes out-of-this-world things like furniture and décor from scrap wood he sources from various places. I had brought Jeff Miller, a former classmate of mine from our undergrad days and a fellow South Jerseyan, on board for a project we did for Adidas in their new office space in NYC—he built four styles of frames for us for that job, about twenty or so in total (it may have been more), and they were phenomenal. I knew he’d blow this one out of the park, too. I convinced my boss to let him do it and yup!

He did it again.

All-in-all, this job was a success and the clients were really happy with the outcome.

—

Client: Top Hops Brewing Company (via drive21)

Project: Top Hops Essex Crossing Market

Fabricators: XDFOUR; Jeff Miller